Protecting your LED Video Wall

Direct View LED video walls are increasingly THE walls in a variety of environments, from flagship retail to shopping mall concourses. This type of digital signage can look amazing, but they can also make people who have experience with LED very nervous - because LEDs and the general public don't always play well together.

Get close to a big conventional LED display that's within reach of people and you will likely start to notice dead, damaged, or missing light pixels - because the surface-mounted LED light emitters are just lightly soldered in place and are highly susceptible to accidental or intentional damage.

When I still lived in Toronto and got into the city center by commuter rail, my morbid curiosity would inevitably lead me over to an ATM machine for a national bank that was surrounded by a direct view LED video wall, mostly showing nature scenes. The point of the video, alone, raised questions, but my interest was always in the state of the display. Tens of thousands of people pass through Toronto Union Station daily, many of them carrying all manner of bags. If you looked closely, you could see all the inadvertent damage to the display, particularly at the corners where people brushing by also brushed off the electronics.

When I was in Taiwan back in 2019, I was encouraged to see a huge indoor LED array inside the lobby of a national bank. It was a set-up that was an attraction on its own, and the bank and building operators had such a problem with kids and adults accidentally damaging the display that it had barriers and a full-time security guard shooing away people who got too close.

Repairs are costly, and the image-conscious brands who spend six figures or more on high-profile video walls won't tolerate having something in view that looks battered and bruised.

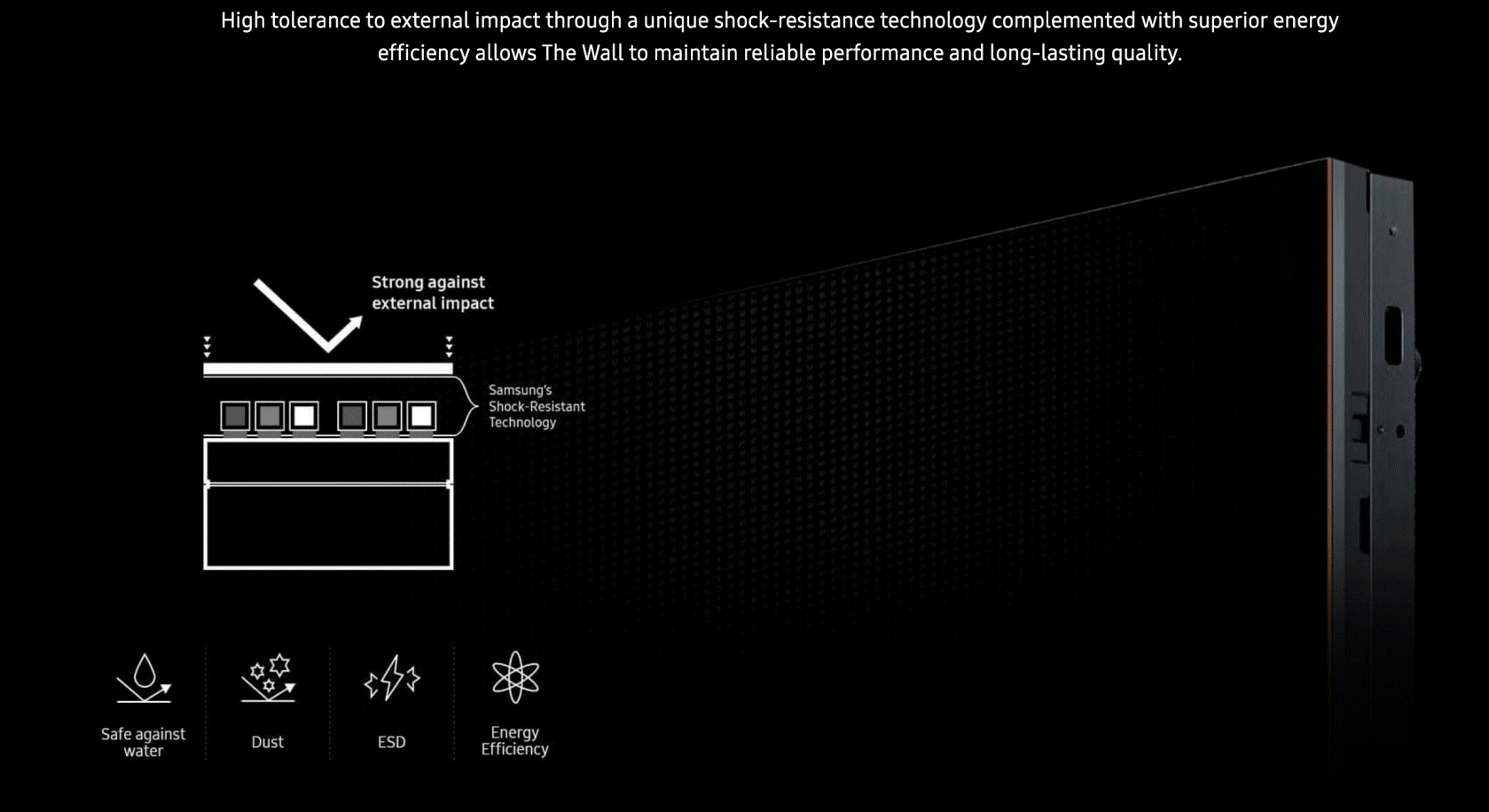

Fortunately, manufacturing advances are starting to alleviate concerns. Several DV LED manufacturers now market LED displays with hardened surfaces that will stand up to modest impacts, static, and even accidental spills. The technology is generically called Glue On Board, or GOB. I've also seen it described as Adhesive On Board. But the term I am warming to, because GOB sounds more like a hack than a manufacturing advance, is Engineered Coating.

I got that description from Gary Feather, the CTO at the Atlanta-based LED manufacturer NanoLumens, who expects widespread adoption of these coatings. We spoke at length about the technology in a recent podcast interview. In effect, the modules that tile together to result in LED display cabinets all have some sort of epoxy coating that protects the light chips but does not trap the heat. Watch the full podcast here.These hardened coatings for conventional surface-mounted LED displays have been around for more than three years, but most of the early adopters were smaller or mid-tier players. They started showing up at trade shows by 2018-19, through manufacturers like CreateLED, Cedar, and LEDMAN. The big guys - the Absen, Leyards, and Unilumins - did not have it, though they were undoubtedly testing. The technical challenges are things like ensuring heat gets out, the epoxy doesn't go from clear to yellow or hazy, and that the layer doesn't affect visual quality.

Feather believes most manufacturers have displays with engineered coatings at some stage of R&D or release. You already see it with major display manufacturers like Sony, Samsung, and LG, via their microLED products. MicroLED uses manufacturing processes that are different from conventional LED, but the coating intention is the same. That invisible shield allows six or even seven-figure video walls to go up and survive close to people. They'll take a bump and even handle a spilled drink.

For a video wall that is out of reach - behind a counter or up on a lobby bulkhead - hardened coatings are not essential. Distance protects them.

But no matter the purpose - from advertising to ambient experiential - any display that is within reach of people - and the things people carry, push and pull - will likely benefit from having a hardened, engineered coating.