Genesis Systems Group Uses Visualization to Streamline Robot Production

Based in Davenport, Iowa, Genesis Systems Group designs and manufactures robots for factory applications such as welding, inspection and material handling. A typical Genesis robot has a footprint of about 20 feet by 20 feet, and some are up to 100 feet long. Their size, weight, and complexity make them expensive and time-consuming to move.

Many potential customers want to see the robot models at trade shows. The option of using visualization to display the robots at trade show booths significantly decreased transport costs for these events.

Visualization enabled Genesis to prototype, test, and refine new models without actually building them, which reduced the cost and time to market for each custom robot. In addition, the technology allowed them to avoid producing robots that needed to

be redesigned because they were a bad fit once installed at the factory. Avoiding that problem also had a positive effect on the customer’s production.

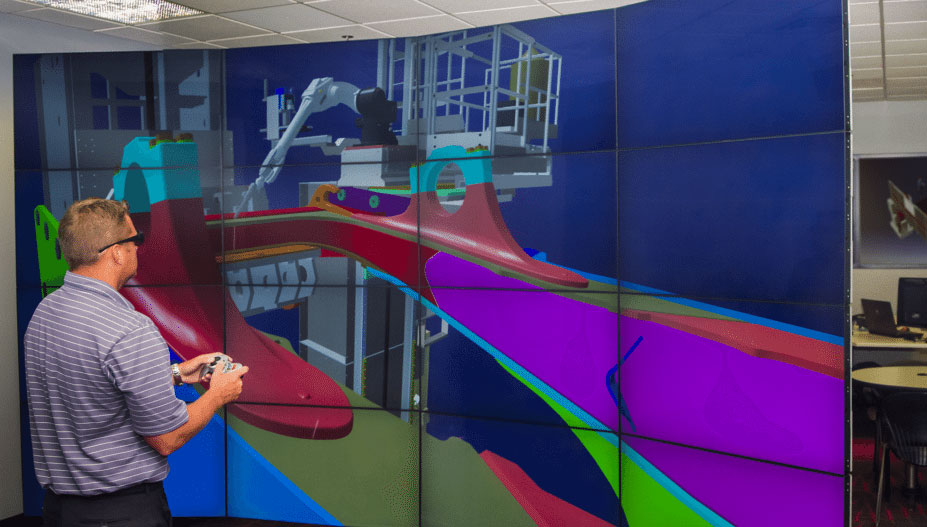

About three years ago, Genesis began working with the AV firm Mechdyne to figure out how visualization technology could address these and other challenges, plus generate competitive benefits. Mechdyne developed a custom solution — subsequently productized as 3DG — featuring screens in a curved, four-by-four tile configuration that could display 2D and 3D content. It’s wide enough that up to eight people can view it simultaneously, thus enabling collaboration rather than one-at-a-time usage.

Existing and prospective customers can use the solution at Genesis’ headquarters to see concepts and review designs, thus streamlining the process because changes can be made before product development begins. "Our goal is to have minimal design changes from concept to fabrication,” says Justan Each, Genesis Virtual Solutions Manager. “With the 3DG, we are seeing that goal come to life.”

Genesis says 3DG directly led to a record sales day, two sales totaling more than $10 million and a two-month reduction in the sales process. “3DG enables us to interact with our customers on a deeper level, and helps bring our simulations to life,” says Travis Sample, Genesis virtual solutions engineer.

Genesis says 3DG also streamlines internal product development because, for example, mechanical engineers and designers now can make design recommendations and plan for production more easily. Applications engineers also have better direction to begin creating programming requirements. These benefits illustrate how visualization can minimize risk for both a business and its customer by enabling both parties to collaborate more effectively on highly complex projects. "It's a big risk for customers to put their faith in us as an integrator,” Each says. “It's a large capital expenditure for a lot of different manufacturing facilities. Showing them what we provide before they make a purchase is very powerful."

Improved Company-Wide Collaboration

Genesis is an example of how visualization can break down silos between departments, thus enabling them to collaborate more efficiently. An internal design review often consists of programmers, tooling designers and other disparate teams, who now can use 3DG to see how their work fits together — and where it doesn’t. “There was always that back and forth of: ‘You didn’t design it correctly. Well, you’re not assembling it the way it should be,’” Each says. “It’s getting everybody in to focus on one goal.”

Avoiding problematic designs and minimizing review cycles — both internal and external — directly benefits Genesis’ bottom line.

“We’re seeing less concept updates,” Each says. “If we have a customer in house, and they can view the concepts, things they would have asked to have changed previously, now they can see it and understand. It [also] really drives home that we need to make this modification. At the end of the day, the customer knows what they’re purchasing. We know what we’re supplying. And they’ve got floor space requirements down to a couple of inches or less.”

Less back-and-forth means faster delivery, which is one way that visualization gives Genesis a competitive edge. “Condensing the calendar is big for us,” Each says. “The competition right now is, ‘How fast can you get machines out to people?”

Another competitive advantage involves pricing. When visualization enables better collaboration between internal teams and with customers, there’s less risk that expensive changes will be required once the robot is built and installed. As a result, Genesis can take some of the risk money out of its quote, thus helping make its robot more competitive from a price standpoint.

Early on, Genesis told Mechdyne that the visualization system had to be portable enough to take to trade shows. “Trade show floor space is extremely expensive,” Each says. “Our machines are pretty large. It relieves that tension of: ‘What machines do we take? What do we showcase this year at the show?’ Now we can take everything we’ve designed in the history of the company and basically view it at a 1:1 scale as you’re immersed in the system.”

Further boosting sales, Genesis uses the system to give exhibition attendees a rough idea of how a robot would fit into their facility and workflow. “We have customers bring part models on thumb drives, and we start building a concept while they’re at lunch or walking around the show floor,” Each says. “They come back a couple of hours later, and we have a rough concept put together of how we’re going to process their parts. It gets the ball rolling.”